Avoid acidic liquids, carbonated beverages, and dairy products in stainless steel bottles to prevent leaching, bacterial growth, or internal damage.

Using stainless steel bottles appropriately will enhance their longevity while keeping your beverages safe and enjoyable. Let’s explore the reasons for avoiding these liquids.

Acidic liquids harm stainless steel durability.True

Highly acidic liquids erode the stainless steel coating.

Why Should Acidic Liquids Be Avoided in Stainless Steel Bottles?

The impact of acidic liquids on stainless steel raises serious concerns about safety, taste, and bottle quality.

Acidic liquids like citrus juices or vinegar can deteriorate the inner lining, causing chemical reactions that compromise both the bottle and its contents.

The Science of Stainless Steel and Acidity

Stainless steel is coated with a thin layer of chromium oxide1, which safeguards it against corrosion. However, acidic liquids interact aggressively with this protective layer over time, especially in enclosed, high-contact environments. Key examples include:

-

Citrus Juices: Storing orange or lemon juice for extended periods leads to material erosion visible on the stainless steel surface2.

-

Vinegar: Highly acidic, vinegar accelerates chemical reactions3, weakening the bottle lining and altering its durability.

Effects of Long-Term Acidity

-

Surface Breakdown: The gradual erosion of the chromium oxide layer exposes the raw stainless steel underneath, leading to rust and structural issues.

-

Metal Exposure Risks: Prolonged acidity can release trace metals like nickel and chromium into liquids, which may impact health and alter flavor profiles.

Scientific studies reveal that liquids with a pH below 4.0, such as lemon juice, amplify these effects, especially when stored for 24 hours or longer.

Preventative Care

-

Quick Rinsing is Critical4: Wash your bottle immediately after carrying acidic beverages.

-

Minimize Storage Time: Stainless steel works best for quick transport, not prolonged storage of acidic drinks.

-

Opt for Specialty Bottles: Use polymer-lined or glass alternatives for frequent storage of these liquids.

A basic cleaning habit paired with alternative storage options will help maintain your bottle’s condition and prevent safety concerns.

Carbonated drinks create pressure risks in bottles.True

CO2 buildup in sealed bottles causes pressure issues.

Can Storing Carbonated Drinks in These Bottles Be Problematic?

You might wonder if bubbly drinks play well with stainless steel bottles. Unfortunately, they present specific challenges tied to pressure and chemical interaction.

Carbonated beverages increase gas pressure inside the cavity, adding strain to seals and potentially contaminating flavors over time.

Pressure Dynamics Inside Bottles

Carbonation in beverages like soda is caused by dissolved CO₂ gas. When confined in a vacuum-insulated stainless steel bottle, the sealed environment traps this gas, which can lead to:

-

Pressure Build-Up: A vacuum-sealed bottle doesn’t release gas, leading to excess internal pressure5 that endangers both seals and structural stability.

-

Damaged Seals Over Time: Constant exposure to pressurized gas degrades the rubber or silicone seals6 crucial for maintaining insulation.

Consider this scenario: A fizzy drink left sealed inside a warm, insulated bottle can surpass safe pressure tolerances, leaving the bottle prone to leaks or distorting its structure.

Flavor and Material Interaction

Carbonation also has subtle effects beyond pressure:

-

Metallic Flavor Overlap7: Extended exposure to carbonated drinks can enhance the interaction of CO₂ with stainless steel, resulting in an altered taste for your drink.

-

Accelerated Corrosion8: When combined with moisture, carbonation may slightly increase acidity, which weakens the bottle lining during consistent use.

Recommendations for Safe Carbonation Storage

-

Vent Gas Frequently: When carrying carbonated beverages, avoid fully sealing the lid. This allows some gas escape to prevent pressure buildup.

-

Limit Usage to Transit: Avoid long-duration storage of carbonated drinks in stainless steel bottles.

-

Use Purpose-Designed Bottles: Opt for glass or plastic bottles engineered to safely hold carbonated drinks.

By reducing pressure-related risks, you enhance both performance and the overall lifespan of your stainless steel bottle.

Dairy drinks lead to bacterial issues.True

Milk residues foster bacteria growth quickly in warmth.

What Issues Arise When Using These Bottles for Milk or Other Dairy Drinks?

Milk may seem convenient for on-the-go hydration, but it’s one of the least ideal liquids for stainless steel.

Dairy products leave sticky residues that are tough to clean, encouraging bacterial growth, unpleasant odors, and bottle discoloration.

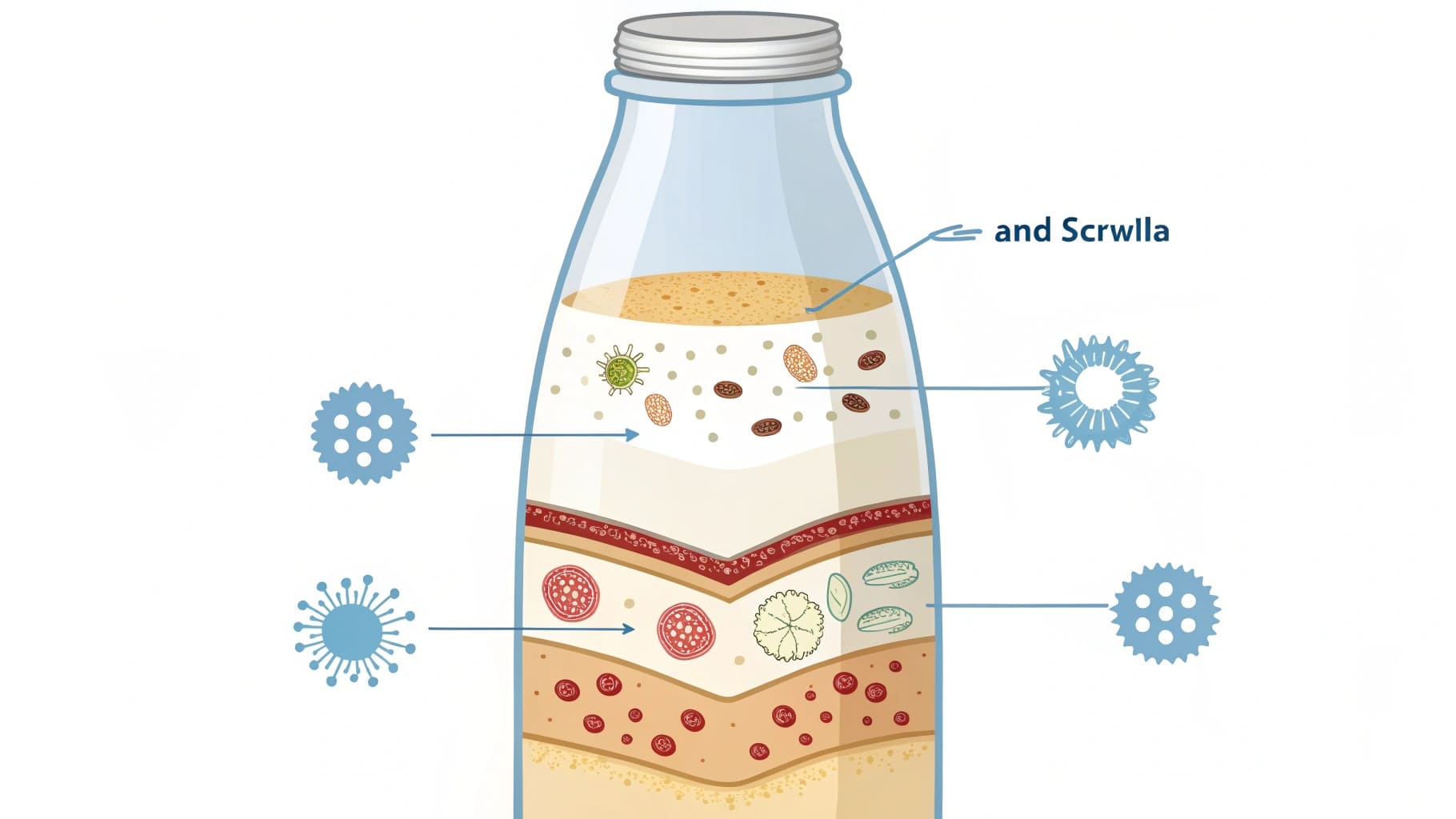

Residue and Bacterial Risks

Milk is rich in proteins and fats that easily adhere to the inner surfaces of stainless steel bottles. Even cleaning thoroughly afterwards may not eliminate this residue entirely, leading to:

-

Accelerated Bacterial Growth9: Milk residues thrive in warm, insulated conditions, which creates a breeding ground for spoilage and unsafe bacteria.

-

Persistent Odors10: Hard-to-clean remnants lead to unpleasant smells, making the bottle less suitable for future use.

For instance, milk stored at room temperature for hours inside a bottle can cause rapid bacterial growth, even if the bottle is rinsed soon afterward.

Stainless Steel Limitations for Dairy

While stainless steel is durable and versatile, its specific design creates additional challenges for dairy use:

-

Impact on Flavor: Stainless steel bottles can retain subtle dairy odors post-cleaning, affecting the fresh taste of future beverages.

-

Cleaning Complexity: Wide-mouth designs make cleaning easier, but narrow-neck versions retain dairy residues more stubbornly.

How to Address Dairy Storage Safely

-

Wash Immediately: Clean bottles as soon as dairy beverages are consumed to avoid residue buildup.

-

Choose Easy-to-Clean Bottles: A wide-mouth design minimizes cleaning complications.

-

Invest in Dairy-Oriented Solutions: Thermal or glass bottles designed specifically for milk retain flavor without risking discoloration.

Mindful cleaning and better material selection solve the complications caused by dairy drinks in stainless steel containers.

Glass suits acidic liquids better than steel.True

Glass resists acid-induced corrosion unlike steel surfaces.

What Are the Best Alternative Storage Options for Restricted Liquids?

Concerned about compatibility between stainless steel bottles and these challenging liquids? Safer options exist for long-term storage or transport needs.

Glass or food-grade polymer designs are excellent alternatives tailored to storing acidic, carbonated, or dairy liquids without compromising safety.

Evaluating Alternative Bottles

| Storage Material | Advantages | Challenges |

|---|---|---|

| Glass Bottles | Non-reactive, preserves flavor | Fragile, heavier than stainless steel |

| Polymer-Lined Bottles | Resistant to acidity, reusable | Less durable than full steel |

| BPA-Free Plastic Bottles | Lightweight, carbonation-friendly | Prone to leaching under high heat |

These options cater to different needs. For example, polymer-lined alternatives protect against acidic liquids, while proper plastic options handle carbonated beverages.

Selecting the Best Option

-

Focus on Chemical Resistance: Glass performs exceptionally with acidic or dairy beverages.

-

Adapt Materials for Pressure: BPA-free plastic is reliable when managing carbonation.

-

Special Features for Dairy: Thermal bottles maintain cold temperatures while ensuring better hygiene.

A thorough consideration of liquid-specific needs ensures safety and long-term satisfaction with your storage choice.

Safety cabinets excel in hazardous liquid storage.True

Fire-resistant cabinets are ideal for laboratory settings.

Conclusion

Acidic liquids, carbonated drinks, and dairy products pose risks to stainless steel bottles, from structural damage to health concerns. Use recommended alternatives for these challenging liquids to ensure both durability and safety.

-

Explore the science of stainless steel's corrosion resistance. ↩

-

Learn about factors leading to stainless steel corrosion. ↩

-

Discusses the impact of vinegar on stainless steel cookware. ↩

-

Explore the importance of proper beverage container rinsing. ↩

-

Discover the effects of high pressure in bottled soda. ↩

-

Understand issues with vacuum seal failure in bottles. ↩

-

Learn why steel containers might cause a metallic flavor. ↩

-

Study the relationship between carbonation and steel corrosion. ↩

-

Dive into issues of bacterial growth in infants' feeding bottles. ↩

-

Explore methods to remove persistent odors from containers. ↩