The Soul of the Flask: More Than Just Steel

A stainless steel insulated flask appears simple, but it is a precisely engineered assembly. Its character—performance, cost, and market position—is determined before the first machine starts. The process begins with two foundational decisions: deconstructing the flask into its core parts and selecting the type of steel.

Deconstructing the Flask

An insulated flask is a double-walled container designed to create a vacuum. It consists of several key parts manufactured separately:

- The Inner Shell: The seamless container holding the beverage. Its material and surface are critical for hygiene.

- The Outer Shell: The exterior body, providing structural integrity and the canvas for finishes.

- The Bottom Cap(s): Used to seal the flask assembly.

- The Lid Assembly: A complex product in its own right, often made from injection-molded, BPA-free plastics like Tritan, with steel shells and silicone gaskets.

Understanding the flask as an assembly is the first step. Each part follows a parallel path before converging for final assembly.

The First, and Perhaps Most Important, Decision: 304 vs. 316 Stainless Steel

"Stainless steel" isn't a single thing. For food-grade products, the choice is almost always between two grades: 304 and 316. This is a strategic choice that defines the product's capabilities and market.

- The Workhorse: 304 (18/8) Stainless Steel. This is the industry standard. Its 18% chromium and 8% nickel composition provides an excellent balance of corrosion resistance, durability, formability, and cost. For most consumer uses, 304 is more than adequate.

- The Marine Grade: 316 (18/10) Stainless Steel. A premium option, 316 steel includes 2-3% molybdenum, which dramatically increases resistance to corrosion from chlorides and acids. This makes it ideal for marine environments, medical implants, or containing acidic drinks.

The choice is a classic engineering trade-off. The superior resistance of 316 steel comes at a significant cost premium (up to 40% higher). The decision isn't about which is "better," but which is appropriate. Using 316 for a coffee mug is over-engineering; using 304 for a sailor's bottle is a design flaw. This technical choice is a foundational marketing decision, signaling whether a brand is competing on value or on premium performance.

From Steel to Shape: The Two Paths of Creation

Once the material is chosen, manufacturing begins. Raw stainless steel arrives as pipes or flat sheets. The factory transforms this stock into the inner and outer shells using one of two primary methods: hydroforming or deep drawing.

Path A: The Water Bulge (Hydroforming)

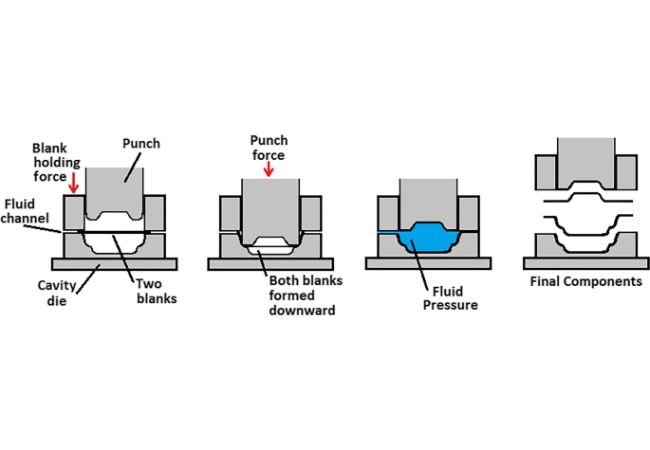

Hydroforming is the most common method for outer shells.

- The Process: A steel pipe is cut to length and placed in a mold. Water is injected at extremely high pressure, expanding the steel to fit the mold's shape.

- Key Characteristic: It creates a part that is open at both ends. A separate bottom cap must be welded on later.

Path B: The Deep Draw (Stretching)

Deep drawing starts with flat sheets of steel.

- The Process: A circular disc is cut and placed in a massive press. A punch drives the metal into a die, forming it into a cup-like shape with a seamless, integrated bottom.

- Key Characteristic: It produces a one-piece, seamless vessel, eliminating the need for a bottom weld on the shell itself. This method is almost always used for the inner shell.

The choice involves a series of trade-offs:

| Feature | Hydroforming (Water Expansion) | Deep Drawing (Stretching) |

|---|---|---|

| Starting Material | Stainless Steel Pipe | Stainless Steel Sheet/Disc |

| Tooling Cost | Lower | Higher |

| Cycle Time | Slower | Faster |

| Part Complexity | Excellent for irregular shapes | Good for cylindrical shapes |

| Material Wastage | Lower | Higher |

| Surface Finish | Generally better, fewer marks | Can be prone to scratches |

| Key Outcome | Bottomless shell (needs a weld) | Seamless shell (integrated bottom) |

Deep drawing, despite its higher initial cost, produces a superior seamless inner liner, eliminating a potential point of failure. This is a fundamental trade-off: investing in better tooling upfront can reduce downstream quality failures.

Refining the Form

Regardless of the path, shells are further refined:

- Shaping/Sizing: A press fine-tunes dimensions for a perfect fit.

- Necking: The upper portion is squeezed to form the bottle's neck.

- Thread Rolling: A machine rolls threads onto the neck to accept the lid.

- Cleaning and Inspection: Shells are washed in ultrasonic baths and undergo their first major quality inspection.

The Critical Juncture: The Pursuit of a Perfect Seal

This is the most critical assembly stage: welding. A single microscopic flaw can render the product useless. The inner shell is fitted inside the outer, the bottom cap is pressed on, and the unit is sent for welding.

Assembly and Welding

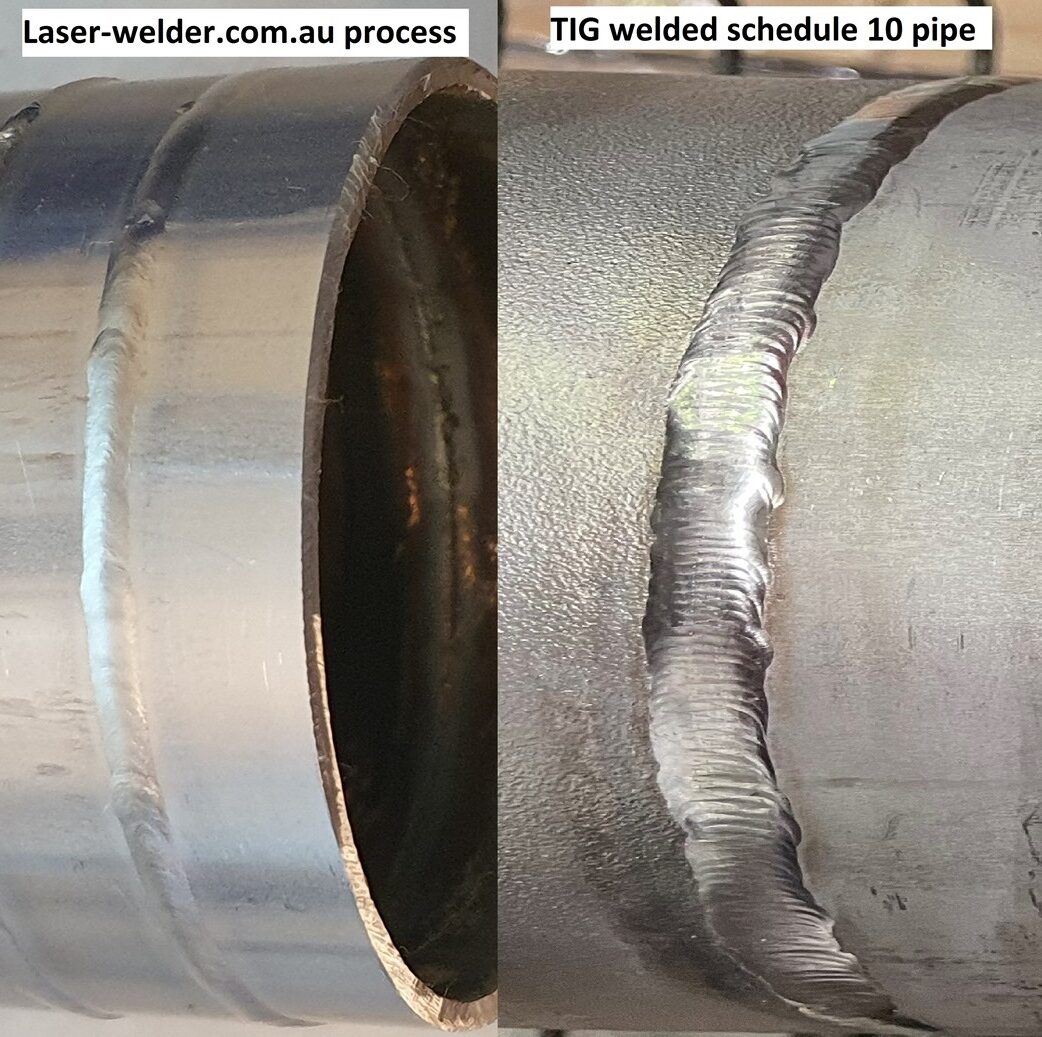

Modern factories rely on two main technologies: traditional Argon Arc (TIG) welding and advanced Laser Welding.

| Feature | Laser Welding | Argon Arc (TIG) Welding |

|---|---|---|

| Principle | Focused beam of light melts metal | Electric arc melts metal |

| Weld Quality | Narrow, clean, smooth seam | Wider, less uniform bead |

| Heat Affected Zone | Extremely small (reduces warping) | Much larger (high risk of warping) |

| Speed & Automation | Significantly faster, ideal for robots | Slower, often manual |

| Cost | High initial equipment investment | Low initial equipment cost |

| Post-Processing | None required | Often requires manual grinding |

Laser welding is an enabling technology for modern flasks. It allows for lightweight, elegant designs and the robotic automation that defines an efficient factory. A factory's investment in laser welding is a strategic one that unlocks higher quality, design freedom, and throughput.

Quality Control: Weld Integrity & Leak Detection

Weld integrity must be rigorously verified.

- Visual Inspection: A trained inspector checks for smoothness, consistency, and obvious defects.

- Water Leak / Submersion Test: The bottle is pressurized with air and submerged in water. Any bubbles indicate a leak.

- Non-Destructive Testing (NDT): Advanced methods like Dye Penetrant Testing or Eddy Current Testing can find flaws invisible to the naked eye.

Creating the Void: The Heart of Insulation

The vacuum between the walls is the flask's "superpower," inhibiting heat transfer. Creating and maintaining this void is a sophisticated process.

The Process: Tailless Vacuuming in a Furnace

The industry standard is "tailless vacuuming."

- Placing the Getter: A small, pill-like "getter" is placed inside the flask assembly. This component is critical for long-term performance.

- Loading the Furnace: Batches of flasks are loaded into a large vacuum furnace.

- Evacuation and Heating: Pumps remove air from the chamber and from between the flask walls via a tiny hole. The furnace heats up (300-500°C) to bake out any residual moisture (outgassing).

- Sealing the Void: A piece of solder placed over the evacuation hole melts at peak temperature (up to 900°C), creating a permanent, airtight seal while the flask is still under vacuum.

- Getter Activation: The intense heat activates the getter. The flasks are then cooled and removed.

The Unsung Hero: Why the Getter is Crucial

A vacuum isn't permanent. Over time, gas molecules trapped in the steel walls will slowly escape ("outgassing"), degrading the vacuum and the flask's performance. The getter is made from highly reactive materials that act as a permanent internal vacuum pump, continuously absorbing these stray gas molecules to maintain the vacuum for the product's lifespan. A cheap flask may omit the getter; it will perform well when new but its insulation will decline over time.

Quality Control: Testing the Void

A failed vacuum is a fundamental defect.

- The Temperature Test: Hot air is blown into the flask. An inspector or thermal sensor checks the outer wall. If it remains cool, the vacuum is good. If it gets warm, the vacuum has failed. This test is performed multiple times: after vacuuming, after polishing, and after final finishing.

The Pursuit of Perfection: Polishing, Coating, and Branding

The flask is transformed from a raw vessel into an aesthetic consumer product.

Inner Beauty: Polishing the Food-Contact Surface

The interior surface must be perfectly smooth to prevent bacteria growth.

| Feature | Mechanical Polishing | Electropolishing |

|---|---|---|

| Process | Physical, abrasive grinding | Electrochemical, removes microscopic layer |

| Surface Result | Smeared, scratched, can trap bacteria | Ultra-smooth, featureless, highly hygienic |

| Corrosion Resistance | Can reduce resistance | Significantly enhances resistance |

| Uniformity & Cost | Labor-intensive, inconsistent | Faster, more efficient, highly uniform |

For a food-grade product, electropolishing is the technically superior method, creating a cleaner, safer, and more durable surface.

Outer Appearance: Coating and Decoration

The exterior is polished to create a base for a coating or brushed/mirrored finish.

- Coating Comparison: Powder Coating is a modern, durable, and eco-friendly process where an electrostatically charged powder is sprayed on and baked, creating a hard finish resistant to chipping. Spray Painting is a traditional, less durable method using liquid paint that is more prone to scratching and releases VOCs.

- Branding the Bottle: Silk Screen Printing is cost-effective for simple, durable designs. Heat Transfer Printing is ideal for complex, photo-realistic graphics but can be less durable. Laser Engraving creates a premium, permanent design by removing the top layer of the coating to reveal the steel beneath.

The Anatomy of Failure: A Process-by-Process Guide to Quality Control

Quality is not achieved by a final inspection, but by a system of checks at every stage.

- Stage 1: Forming: Defects like wrinkling or tearing are caused by mismatches between material and process parameters. Prevention starts with verifying raw materials and precise control over presses.

- Stage 2: Welding: Defects like cracks or porosity are caused by improper parameters or contamination. Quality is ensured by strict adherence to a Welding Procedure Specification (WPS) and 100% leak testing.

- Stage 3: Vacuuming: The primary failure is loss of insulation, caused by a missed weld leak or, more insidiously, long-term outgassing if a quality getter is missing. QC involves rigorous leak testing and repeated temperature checks.

- Stage 4: Finishing: Coating failures like peeling or blistering are almost always caused by improper surface preparation. QC requires extreme cleanliness and controlled environments.

An early-stage error compounds. A small scratch from forming can become a crack during welding, leading to a scrapped product at the final test. The most effective quality control is preventative and front-loaded.

The Economics of a Flask: Deconstructing the Cost

The final cost is a complex function of materials, processes, labor, and efficiency.

The equation is: Cost per Unit = (Materials + Labor + Energy + Overheads) / Yield Rate

Primary Cost Drivers

- Raw Materials: Consistently the largest single cost, driven by the fluctuating price of stainless steel (316 is ~40% more than 304).

- Manufacturing Process & Complexity: More steps and custom tooling increase cost. Laser welding has high upfront costs but can lower long-term costs through speed and higher yield.

- Labor & Automation: Labor is a significant expense. Robotic automation requires large investment but reduces labor costs and increases consistency.

- Production Volume: Economies of scale are powerful. Larger runs reduce per-unit cost by amortizing setup costs and allowing for bulk material purchases.

The Hidden Multiplier: Yield Rate (良品率)

This is the most critical variable. If a factory has a 90% yield rate, the cost of the 10 scrapped units must be absorbed by the 90 good ones. A factory with a 98% yield rate has a fundamentally lower cost structure than one with an 85% yield. High yield is the direct result of investment in quality: better materials, precise machinery, and robust process control. Investing in high-tech processes often results in a lower true cost per quality unit.

The 2025 Frontier: Automation, Sustainability, and Smart Flasks

The humble water bottle is evolving, driven by consumer behavior, regulation, and technology.

Trend 1: The Rise of the Robots (Automation & AI)

Smart manufacturing is the new standard.

- What's Happening: Robotic arms are standard for welding and polishing. AI-powered vision systems perform quality control with superhuman accuracy.

- Why it Matters: Automation leads to unparalleled consistency (improving yield), higher throughput, and improved workplace safety.

Trend 2: The Green Mandate (Sustainability)

Sustainability is a business imperative.

- What's Happening: A push toward using recycled stainless steel (up to 90%), sustainable materials for lids (bamboo, plant-based polymers), and eco-friendly processes like VOC-free powder coating.

- Why it Matters: Consumers purchase based on a brand's values. Compliance with environmental regulations is a mandatory ticket to play in global markets.

Trend 3: The Smart Bottle (Technology Integration)

The bottle is becoming an active, connected device.

- What's Happening: Lids with integrated sensors track hydration via Bluetooth apps. UV-C LED lights in the lid sterilize the bottle and purify water.

- Why it Matters: This shifts the product from housewares to the consumer electronics category, commanding higher prices and opening new business models (e.g., filter subscriptions).

These trends are converging. The winning manufacturers will be those who can master this intersection—using intelligent, automated systems to produce sustainable, tech-integrated products.

Conclusion

The insulated flask, an object of deceptive simplicity, is the product of a long chain of critical decisions. The journey from a sheet of steel to a finished bottle is a story of trade-offs: cost versus quality, speed versus precision, tradition versus technology. The choice between 304 and 316 steel defines the product's market. The decision between deep drawing and hydroforming impacts its structural integrity. The investment in laser welding over TIG welding unlocks a higher level of quality and design freedom. Hidden components like the getter determine not just how the flask performs today, but if it will perform a year from now. Ultimately, a flask's final quality and cost are not born from a single action, but are the sum total of a thousand choices made on the factory floor, all governed by the unforgiving multiplier of the yield rate. As automation and smart technology redefine the frontier, the unseen machine behind the flask will only grow more complex, continuing its quiet pursuit of the perfect, enduring void.