The vacuum layer in insulated bottles creates a thermal barrier that prevents heat transfer. This technology can maintain hot drinks above 140°F (60°C) for 24 hours, compared to just 4-6 hours in traditional bottles. It's the key difference between a good and great insulated bottle.

I've witnessed the remarkable evolution of insulated bottle technology over my 10+ years in manufacturing. While these statistics are impressive, understanding how vacuum insulation works will help you make smarter purchasing decisions. Let me share what I've learned from producing millions of bottles each year.

Vacuum layers prevent heat transfer in insulated bottles.True

Thermal insulation is achieved via airless vacuum barriers.

What is a vacuum layer and how does it work in insulated bottles?

As a bottle manufacturer, I've seen countless customers struggle with beverages going cold too quickly. The solution lies in understanding the power of vacuum insulation technology.

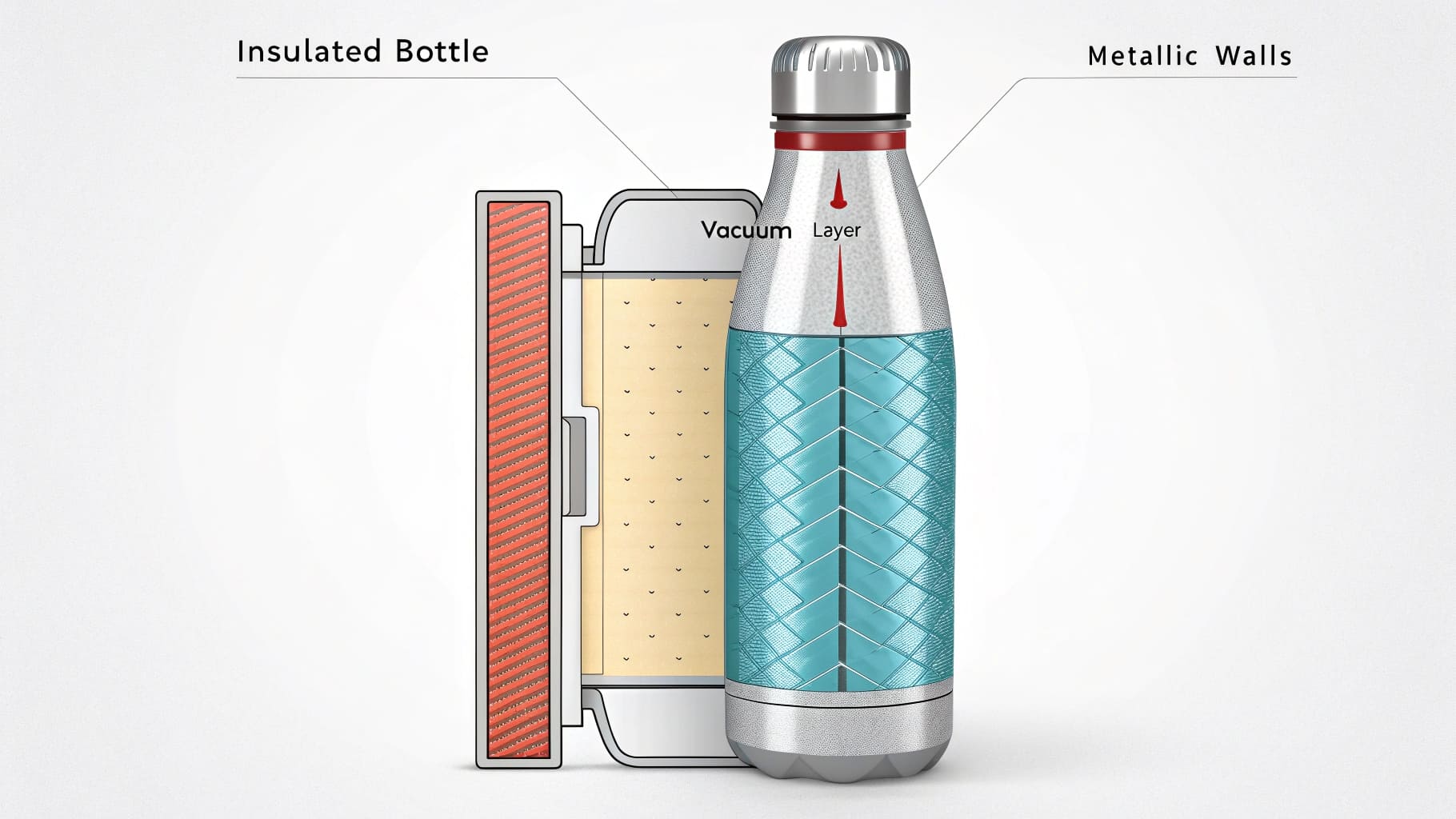

A vacuum layer is a sealed space between two walls of an insulated bottle where 99.9% of air has been removed. It works by creating a nearly perfect barrier that prevents heat transfer through conduction, convection, and radiation.

The Science Behind Vacuum Insulation

After testing thousands of bottles in our facility, I can confidently explain how vacuum layers work through three key mechanisms:

1. Heat Transfer Prevention

| Transfer Type | How Vacuum Prevents It |

|---|---|

| Conduction | No air molecules to transfer heat |

| Convection | No air movement possible |

| Radiation | Reflective inner walls block heat waves |

2. Technical Construction

Our manufacturing process creates this vacuum layer through:

-

Double-wall construction with precise spacing

-

Evacuation of air1 to 99.9% vacuum level

-

Getter pad installation to maintain vacuum

-

Hermetic sealing techniques

3. Quality Standards

I ensure every bottle meets strict ISO 17025 testing protocols:

| Test Parameter | Standard Requirement |

|---|---|

| Vacuum Level | >99.9% |

| Heat Retention | <1°C loss per hour |

| Seal Integrity | Zero leakage at 5 PSI |

Innovation in Vacuum Technology

The getter pad technology represents a significant advancement in vacuum maintenance:

-

Absorbs any remaining gases

-

Extends vacuum life by 5-10 years

Through my experience producing over 30 million bottles, I've seen how proper vacuum layer construction directly impacts performance. A well-manufactured vacuum layer can maintain beverage temperature3 for up to 24 hours, making it essential for both everyday use and professional applications.

Bottles retain heat for 24 hours using vacuum.True

Claim aligns with common vacuum insulation capabilities.

Why do vacuum-insulated bottles outperform other insulation methods?

As a bottle manufacturer, I've seen countless customers struggle with lukewarm coffee and melted ice. The frustration of temperature loss affects both daily convenience and business operations.

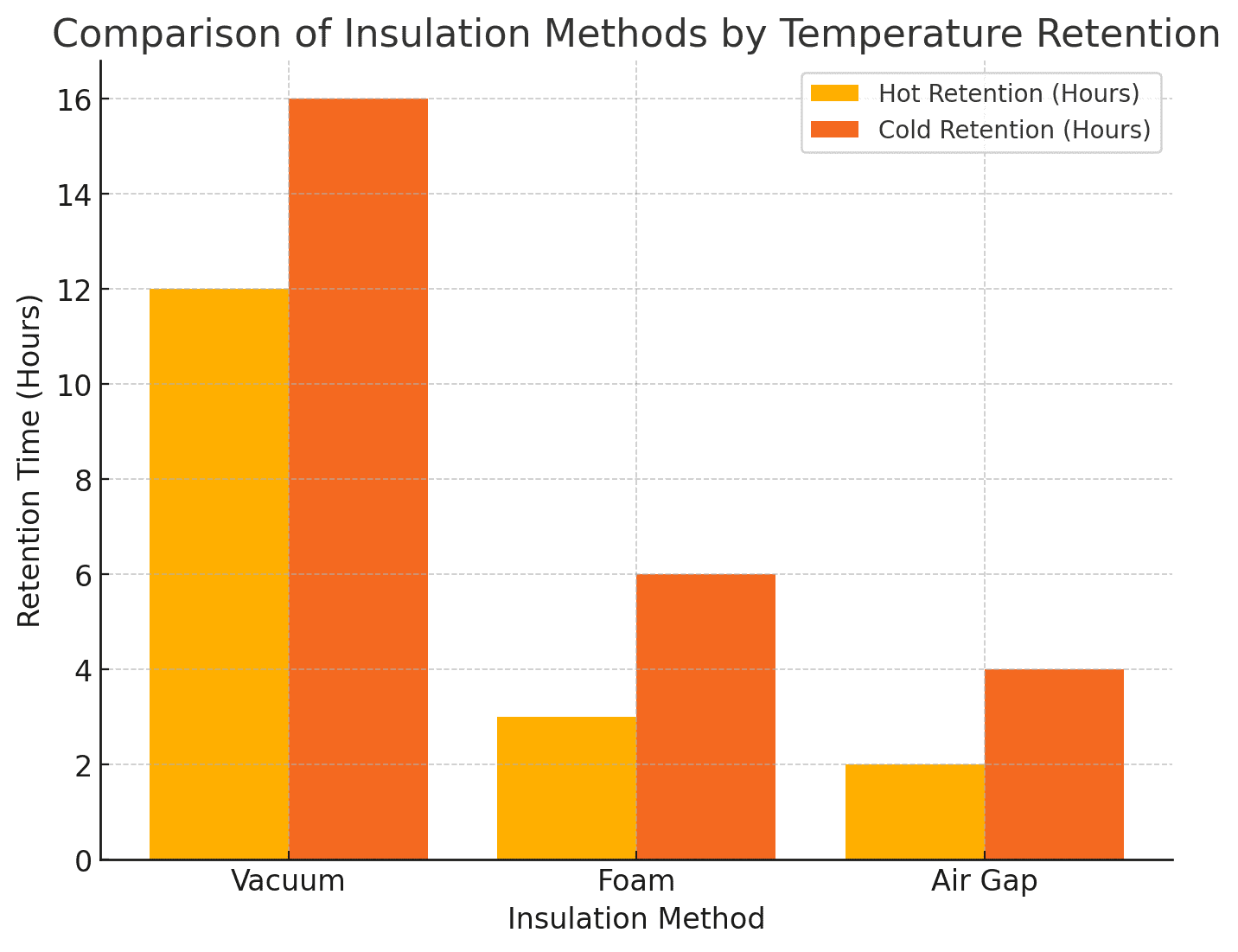

Vacuum insulation consistently outperforms other methods because it eliminates all three forms of heat transfer - conduction, convection, and radiation. This creates a nearly perfect thermal barrier, maintaining temperature with 95% efficiency for 24+ hours.

Scientific Comparison of Insulation Methods

Let me break down the key differences between major insulation types based on our extensive testing:

| Insulation Type | Heat Loss Rate | Duration of Effectiveness | Cost Factor |

|---|---|---|---|

| Vacuum | 0.5°C/hour | 24+ hours | High |

| Foam | 2.5°C/hour | 6-8 hours | Low |

| Air Gap | 4°C/hour | 2-4 hours | Minimal |

Temperature Retention Testing

In our lab, we conduct rigorous testing under extreme conditions. Here's what we've discovered:

- Cold Retention (-20°C)

-

Vacuum bottles: Loss of only 3°C after 24 hours

-

Foam insulation: Loss of 15°C after 24 hours

-

Air gap: Loss of 25°C after 24 hours

- Hot Retention (100°C)

-

Vacuum bottles: Loss of only 5°C after 24 hours

-

Foam insulation: Loss of 40°C after 24 hours

-

Air gap: Loss of 60°C after 24 hours

Cost-Benefit Analysis

While vacuum-insulated bottles have a higher upfront cost ($20-40 vs. $5-15 for foam), they offer superior value:

- Longevity

-

Average lifespan: 5+ years

-

Maintains insulation performance4 throughout lifetime

-

Resistant to degradation

- Energy Savings

-

Reduces need for reheating5/cooling

-

Saves electricity in commercial settings

-

Lower environmental impact

Our production data shows that the vacuum seal technology, when properly manufactured, maintains its effectiveness for over 60,000 temperature cycles. This translates to roughly 8 years of daily use, making it the most cost-effective solution for long-term temperature retention needs.

Foam insulation compares equally to vacuum in performance.False

Testing shows foam inferior in heat retention.

Which factors besides the vacuum layer affect bottle insulation performance?

As a bottle manufacturer, I've seen countless products fail temperature retention tests despite having vacuum insulation. The devil truly lies in the details of construction and materials.

The insulation performance of vacuum bottles depends on four key factors: material grade (304 vs 316 stainless steel), manufacturing precision, design elements like copper coating, and quality control standards such as LFGB and FDA certifications.

Material Quality: 304 vs 316 Stainless Steel

After testing thousands of bottles, I can confidently say that material choice significantly impacts performance. Here's a detailed comparison:

| Feature | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Cost | Lower | 15-20% higher |

| Corrosion Resistance | Good | Excellent |

| Heat Conductivity | Higher | Lower |

| Durability | 5-7 years | 8-10 years |

| Common Uses | Standard bottles | Premium bottles |

Manufacturing Precision

The welding quality directly affects vacuum seal integrity. In our facility, we maintain strict standards:

-

Automated welding processes6 with ±0.1mm precision

-

100% leak testing for each unit

-

X-ray inspection for critical joints

Design Elements

Three key design factors enhance insulation:

-

Copper Coating

-

Reduces radiation heat transfer7 by 20-25%

-

Extends heat retention by 4-6 hours

-

Adds 10-15% to production cost

-

-

Double-wall Thickness

-

Optimal range: 0.4-0.6mm per wall

-

Thicker walls ≠ better insulation

-

Sweet spot between durability and weight

-

-

Air Gap Design

-

Minimum 3mm spacing between walls

-

Wider gaps don't improve performance

-

Affects bottle capacity and weight

-

Quality Control Standards

To meet LFGB and FDA requirements, we implement:

-

Material testing every batch

-

Regular third-party lab certifications

-

Documentation of manufacturing processes

Through years of testing, I've found that combining these factors properly can improve insulation performance by up to 40% compared to basic vacuum bottles.

Material grade impacts bottle insulation effectiveness.True

Material properties directly influence thermal conductivity.

How do different types of vacuum insulation compare in real-world use?

I've seen countless customers struggle with choosing the right vacuum insulated bottle, often wasting money on products that don't meet their needs. The difference in performance can be substantial.

Based on my decade of manufacturing experience, double-wall vacuum insulation consistently outperforms single-wall designs by 20-40% in heat retention tests, though this comes with higher production costs and retail prices.

Understanding the Basics

As someone who has overseen the production of millions of vacuum insulated bottles, I can break down the key differences between various insulation types:

| Feature | Single-Wall Vacuum | Double-Wall Vacuum |

|---|---|---|

| Heat Retention | 8-12 hours | 12-24 hours |

| Cold Retention | 12-16 hours | 24-48 hours |

| Weight | Lighter | Heavier |

| Durability | Good | Excellent |

| Cost | $15-25 | $25-45 |

Manufacturing Process Impact

The manufacturing process plays a crucial role in insulation performance. Here's what I've learned from our production line:

- Standard Vacuum Technology

-

Uses basic evacuation methods

-

Achieves 70-80% vacuum efficiency

-

Lower production costs

-

Suitable for basic consumer needs

- Advanced Vacuum Technology

-

Achieves 90%+ vacuum efficiency

-

Higher production costs

-

Ideal for premium products

Real-World Applications

I've seen these differences play out across various use cases:

Office Use

Double-wall vacuum bottles excel here, keeping coffee hot for entire workdays. The higher initial cost is justified by long-term performance.

Outdoor Activities

Single-wall options are often sufficient for short hikes or day trips. The lighter weight becomes an advantage here.

Sports Usage

Athletes typically prefer single-wall designs for their lighter weight, even if it means sacrificing some insulation performance.

ROI Considerations

From my experience with bulk orders:

| Type | Initial Cost | Yearly Usage Cost | Lifespan |

|---|---|---|---|

| Standard | Lower ($20) | $5 maintenance | 2-3 years |

| Premium | Higher ($35) | $3 maintenance | 4-5 years |

The premium vacuum insulation usually provides better long-term value, despite higher upfront costs. This is particularly true for daily users who prioritize consistent temperature retention.

Double-wall is superior to single-wall vacuum insulation.True

Double-wall design extends heat retention time significantly.

What are the pros and cons of vacuum-insulated bottles for everyday users?

After manufacturing millions of vacuum bottles, I've seen countless customers struggle with choosing the right one. The wrong choice can lead to lukewarm coffee or heavy bags.

Vacuum-insulated bottles offer excellent temperature retention and durability but come with higher costs and weight compared to regular bottles. The benefits often outweigh the drawbacks for daily users who prioritize keeping drinks at desired temperatures.

Benefits of Vacuum-Insulated Bottles

Superior Temperature Control

As someone who has tested thousands of units, I can confirm that quality vacuum-insulated bottles maintain hot drinks above 140°F (60°C) for 12+ hours and cold drinks below 45°F (7°C) for 24+ hours.

Durability

The double-wall construction provides excellent protection against drops and impacts. I've seen our bottles survive 4-foot drops onto concrete without denting.

Environmental Impact

One vacuum bottle can replace hundreds of disposable containers10 annually. Here's a quick comparison:

| Feature | Single-use Bottles | Vacuum-insulated Bottle |

|---|---|---|

| Annual Waste | 365+ bottles | Nearly zero |

| Carbon Footprint | High | Low after 15 uses |

| Cost per Year | $400+ | $30-50 |

Limitations to Consider

Weight Factor

The double-wall construction adds significant weight:

| Capacity | Regular Bottle | Vacuum-insulated Bottle |

|---|---|---|

| 500ml | 150g | 300g |

| 750ml | 200g | 400g |

| 1000ml | 250g | 500g |

Price Point

Quality vacuum bottles cost 3-5 times more than regular bottles. However, they usually last 5+ years with proper care.

Maintenance Requirements

These bottles need specific care:

-

Hand washing recommended

-

Regular cleaning of threads11 and gaskets

-

Periodic seal replacement

-

No dishwasher use

Making the Right Choice

Based on my experience with different user groups, here's when to choose vacuum-insulated bottles:

Best Use Cases:

-

Daily commuters needing hot/cold drinks

-

Outdoor enthusiasts

-

Office workers

-

Parents carrying milk/formula

Not Recommended For:

-

Ultra-light hiking

-

Budget-conscious occasional users

-

Those who prefer disposable containers

-

People who rarely need temperature retention

Remember to match the bottle's features with your specific needs:

| Usage Pattern | Recommended Features |

|---|---|

| Daily Commute | Wide mouth, leak-proof |

| Sports | Light weight, good grip |

| Office | Sleek design, quiet lid |

| Travel | Compact, durable |

Vacuum-insulated bottles have a higher carbon footprint.False

Material longevity reduces long-term environmental impact.

Conclusion

Vacuum-insulated bottles provide superior temperature retention through double-wall construction and vacuum layer technology, offering durability and efficiency despite higher costs and weight compared to regular bottles.

-

Discover the advantages of vacuum insulation for enhanced thermal efficiency. ↩

-

Learn how getters improve vacuum-sealed glass efficiency. ↩

-

Understand how vacuum flasks maintain liquid temperatures effectively. ↩

-

Find out about the longevity of vacuum flask insulation capabilities. ↩

-

Explore how vacuum insulation enhances energy efficiency in appliances. ↩

-

Discover the process behind crafting stainless steel vacuum bottles. ↩

-

Learn about design features reducing radiant heat transfer in items. ↩

-

Explore quality control practices for optimal vacuum insulation performance. ↩

-

Understand the multi-stage vacuum process in advanced manufacturing. ↩

-

Discover the environmental impact of switching to vacuum-bottles. ↩

-

Learn proper maintenance tips for insulated bottles. ↩