The fastest way to cut shipping costs is to rethink your packaging strategy. Ship bottles and gift boxes separately. Use proper carton specs. Work with loading professionals. These three changes alone can save you up to two-thirds of your freight costs on gift set orders.

After 20 years in the water bottle export business, I have seen every packaging mistake. Crushed cartons from humidity. Wasted container space from fancy boxes. Wrong SKU codes on packaging. Most of these problems have simple solutions. But many buyers learn them the hard way.

Shipping pre-assembled gift boxes wastes container spaceTrue

Gift boxes add 3-4x more volume than bottles alone.

All freight costs are fixed and non-negotiableFalse

Packaging optimization often cuts more cost than rate negotiation.

Why Do Pre-Assembled Gift Boxes Waste So Much Container Space?

You want premium presentation. Gift boxes look great on retail shelves. But shipping them pre-assembled eats container space like nothing else.

A pre-assembled gift box holding 2-3 bottles takes the same volume as 10-15 bottles in standard packaging. The smarter approach: ship bottles in regular cartons and gift boxes flat-packed separately. Assemble at your warehouse. This cuts shipping costs by roughly two-thirds.

The Math Behind the Waste

Let me break this down with real numbers. A typical pre-assembled gift set box measures 30cm x 20cm x 25cm. It holds 2 bottles. That is 15,000 cubic centimeters per set.

The same 2 bottles in standard cartons take about 4,000 cubic centimeters. The pre-assembled gift box adds 11,000 cubic centimeters of dead space. Multiply this across a full container order.

| Packaging Method | Volume per 2 Bottles | Bottles per 40ft Container |

|---|---|---|

| Pre-assembled Gift Box | 15,000 cm³ | ~13,000 bottles |

| Standard Carton + Flat Gift Box | 4,000 cm³ | ~40,000 bottles |

| Difference | 3.75x more space wasted | 27,000 fewer bottles |

I had this conversation with a buyer last year. He wanted 20,000 gift sets shipped pre-assembled. I showed him the numbers. We shipped bottles in standard cartons and flat-packed gift boxes in separate pallets. Same container. Same order. He assembled them at his warehouse.

His reaction when I first suggested this? "Too much trouble." His reaction after seeing the freight quote comparison? "Let's do it your way."

The assembly takes time. But the savings cover extra labor costs many times over. Most buyers accept this approach once they see the actual shipping cost breakdown1.

Flat-packed gift boxes save significant freight costsTrue

Separating boxes from bottles cuts volume by 65-75%.

Warehouse assembly is too expensive to justifyFalse

Assembly labor costs far less than the freight savings.

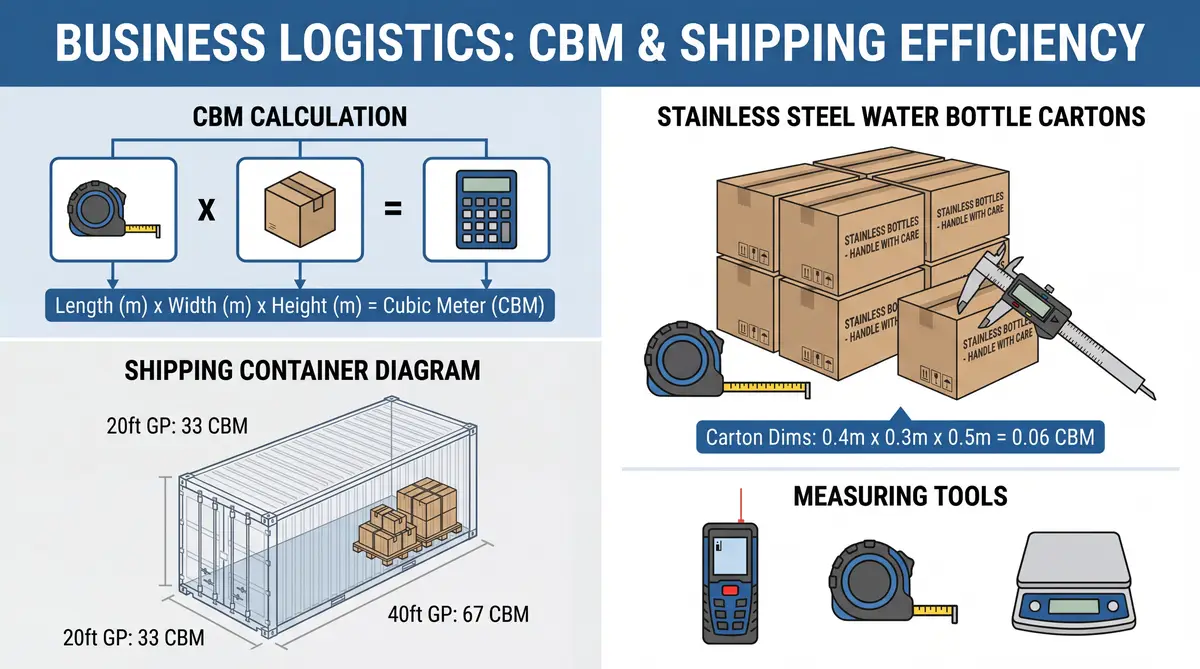

How Do You Calculate CBM Without Making Mistakes?

You run your CBM calculation. The numbers look good. The container arrives. Suddenly you have 15 extra cartons that do not fit. Sound familiar?

Never calculate CBM from product capacity alone. Use actual outer carton dimensions. Add 5-10% buffer for loading gaps. Have a professional loader verify before production starts.

Common CBM Calculation Errors

I see two mistakes repeatedly. Buyers calculate based on bottle size. Suppliers estimate based on capacity in milliliters. Both approaches fail.

A 500ml bottle does not have a standard size. Different designs have different dimensions. A slim 500ml bottle and a wide 500ml bottle need completely different carton specifications2. The ISO 668 standard3 defines container dimensions, but internal usable space depends on your carton arrangement.

| Calculation Method | Accuracy | Risk Level |

|---|---|---|

| Based on ml capacity | Low | High - major space miscalculation |

| Based on product dimensions | Medium | Medium - ignores carton specs |

| Based on outer carton size | High | Low - actual shipping unit |

| Verified by loading professional | Highest | Minimal - accounts for stacking |

Here is what happened with a Canadian customer last year. We calculated everything based on carton dimensions. Left what we thought was proper buffer space. The loading team was too good. They optimized every gap. We ended up with space for 15 extra cartons.

Lucky for us, the customer had some loose samples to fill the space. But it could have gone the other way. We could have promised more than we could fit.

Now I always have our loading team review the calculations before confirming quantities. Their experience catches things that spreadsheets miss. Working with reliable manufacturing partners4 who understand logistics makes a real difference.

CBM must be calculated from outer carton dimensionsTrue

Inner product size ignores packaging overhead.

Spreadsheet calculations replace professional verificationFalse

Experienced loaders catch stacking issues spreadsheets miss.

What Packaging Protects Your Water Bottles During Ocean Freight?

The container spent 30 days at sea. You opened it. The outer cartons looked like wet cardboard. The bottles inside had rust spots. This is not about sea water. It is about humidity.

Ocean containers face extreme humidity changes. Protect your shipment with three layers: reinforced carton walls, inner plastic film wrap, and outer shrink wrap. Skip any layer and you risk moisture damage.

The Three-Layer Protection System

Sea freight is harsh. Containers sit in tropical ports. Temperature swings cause condensation inside. Regular cardboard absorbs this moisture and weakens.

I learned this the hard way. One shipment arrived with damaged outer boxes. Only one carton actually broke. But two bottles inside got scratched. The problem was not the sea water. It was the humid air inside the container over 25 days. According to Drewry Maritime Research5, container humidity can exceed 90% during tropical passages.

| Protection Layer | Purpose | Skipping Risk |

|---|---|---|

| Reinforced carton (5-ply) | Structural strength | Crushed products |

| Inner plastic film | Moisture barrier | Rust, water spots |

| Outer shrink wrap | Secondary seal | Film tears, dust entry |

Good packaging costs more upfront. A reinforced 5-ply carton costs about 15-20% more than a standard 3-ply. The plastic film adds another small cost. But compare this to a claim for damaged goods.

The difference between good and bad packaging shows immediately when you see them side by side. Thick walls versus thin. Firm structure versus flimsy. Proper sealing versus loose tape. Buyers rarely inspect packaging quality during factory visits6. They should.

Using proper stainless steel grades7 helps prevent rust, but packaging protection remains critical regardless of material quality.

Three-layer packaging prevents humidity damageTrue

Each layer serves a specific protective function.

Standard 3-ply cartons are sufficient for sea freightFalse

Regular cardboard absorbs moisture and weakens during 30-day voyages.

How Many Water Bottles Fit in a 20ft or 40ft Container?

You need to plan inventory. You need to budget freight. The first question is always the same. How many bottles fit?

A 20ft container holds approximately 20,000 standard 500ml insulated bottles. A 40ft container holds about 40,000. These numbers assume standard carton packing without gift boxes. Actual capacity depends on bottle design and carton configuration.

Container Capacity Reference

These numbers give you planning estimates. Real capacity varies based on many factors. Bottle shape matters. Carton arrangement matters. Loading skill matters.

| Container Size | Cubic Capacity | 500ml Bottles (Est.) | 750ml Bottles (Est.) |

|---|---|---|---|

| 20ft Standard | 33 CBM | ~20,000 | ~15,000 |

| 40ft Standard | 67 CBM | ~40,000 | ~30,000 |

| 40ft High Cube | 76 CBM | ~45,000 | ~34,000 |

The loading team makes a real difference here. Professional loaders know how to minimize dead space. They understand how to stack different carton sizes together. They can squeeze 5-10% more into the same container. The World Shipping Council8 provides container specifications, but real-world loading efficiency depends on experience.

We work with experienced loading teams who specialize in drinkware shipments. They have loaded thousands of containers. They know exactly how to arrange cartons to maximize every cubic meter.

My advice for first-time buyers placing full container orders: trust your supplier's logistics experience. Ask about their loading process. Ask if they use professional loading teams. The difference shows up in your landed cost per unit9. Working with suppliers who understand manufacturing and logistics together10 simplifies the entire process.

Professional loaders add 5-10% more capacityTrue

Experience with carton stacking maximizes every gap.

Container capacity is fixed regardless of loading skillFalse

Loading technique significantly affects actual utilization.

Conclusion

Smart packaging saves more than fancy negotiation. Ship gift boxes flat. Calculate CBM from carton dimensions. Use three-layer protection. Work with experienced loaders. These basics cut costs and prevent damage on every shipment.

-

Full container shipping requires understanding all cost components including packaging overhead ↩

-

Different bottle shapes require different carton configurations even at same ml capacity ↩

-

ISO 668 is the international standard for freight container dimensions and specifications ↩

-

Experienced suppliers include logistics planning as part of their service ↩

-

Drewry is a leading maritime research consultancy tracking shipping industry data ↩

-

Factory audits should include packaging line inspection and material verification ↩

-

304 and 316 stainless steel have different corrosion resistance properties ↩

-

World Shipping Council represents the international liner shipping industry ↩

-

Landed cost includes freight, duties, and all logistics expenses per unit ↩

-

Vertically integrated suppliers control both production and shipping quality ↩