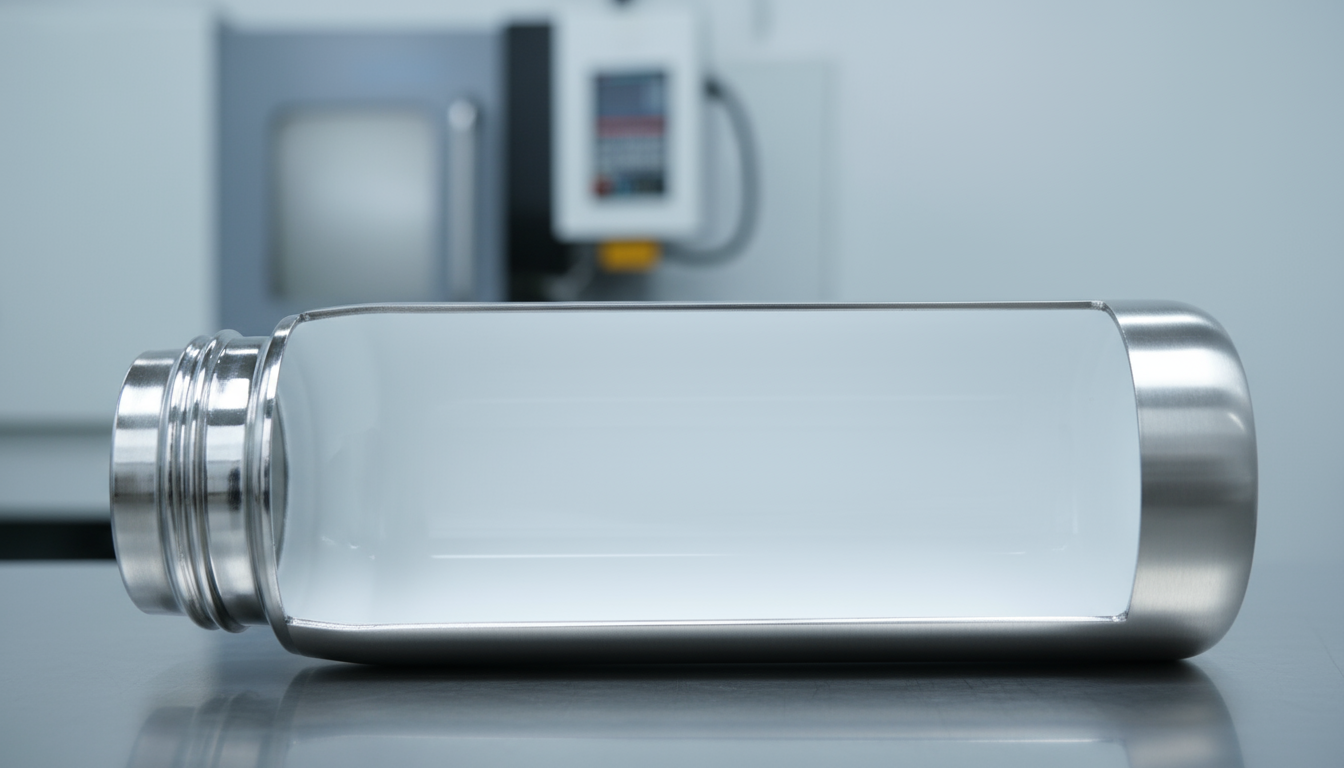

Ceramic-coated stainless steel bottles offer three key B2B advantages: superior durability that preserves your brand image longer, complete taste purity that elevates user experience, and clear technological justification for premium pricing that shifts purchasing decisions from cost-per-unit to investment-per-impression.

I learned this lesson the hard way when our client's $15,000 promotional bottle order became a brand liability. Within six months, half the recipients had bottles with chipped logos and scratched surfaces. That failure taught me why ceramic coating matters for B2B buyers who need lasting brand ambassadors, not disposable marketing materials.

Ceramic-coated bottles offer B2B advantages like durability, taste purity, and premium pricing justification.True

The text explicitly states these as the three key B2B advantages of ceramic-coated stainless steel bottles.

Ceramic-coated stainless steel bottles are primarily chosen for their low unit cost.False

The text indicates they justify 'premium pricing' and shift purchasing to 'investment-per-impression,' not low cost.

Why Choose a Ceramic-Lined Over a Traditional Stainless Steel Bottle

Your brand reputation depends on products that maintain their premium appearance throughout their useful life. Standard bottles create negative associations when they look worn after minimal use.

Ceramic-lined bottles solve the primary aesthetic failure of standard bottles through superior scratch resistance and coating durability. The ceramic interior also eliminates metallic taste transfer, creating a pure drinking experience that reflects positively on your brand.

The fundamental difference lies in material hardness and chemical inertness. I discovered this when analyzing customer complaints about our standard bottles. The pain point analysis revealed coating peeling as the top issue, severely damaging perceived value.

Durability Comparison

| Feature | Standard Stainless Steel | Ceramic-Coated |

|---|---|---|

| Scratch Resistance | Basic (2-3H hardness) | Superior (≥3H hardness) |

| Coating Adhesion | Paint-based, prone to chipping | Nano-ceramic bonding |

| Brand Logo Longevity | 3-6 months before damage | 2+ years pristine condition |

| Impact Resistance | Dents easily show | Ceramic layer protects base metal |

Chemical Properties

The ceramic coating creates an inert barrier that prevents any interaction between your beverage and the metal surface1. Standard 304 stainless steel, while food-safe, can impart subtle metallic notes, especially with acidic drinks like lemon water or coffee.

This matters for B2B buyers because user satisfaction directly impacts brand perception. When someone enjoys pure-tasting coffee from your branded bottle every morning, they associate your company with quality and attention to detail. Conversely, metallic-tasting water creates negative subconscious associations.

Ceramic lining enhances bottle appearance and eliminates metallic taste transfer.True

The text states ceramic provides superior scratch resistance, durability, and eliminates metallic taste.

Ceramic-lined bottles are less durable and prone to aesthetic wear.False

The text highlights ceramic's superior scratch resistance and coating durability, solving aesthetic failure.

Is the Ceramic Coating in Water Bottles Safe and Durable

Safety concerns often drive B2B purchasing decisions, especially for corporate gifts that reflect company values. Ceramic coatings must meet stringent safety standards while delivering promised durability benefits.

Ceramic coatings use FDA-approved, food-grade materials that are completely non-toxic and chemically inert. The nano-ceramic modified polyurethane formulation provides hardness ratings of ≥3H, significantly exceeding standard paint coatings for long-term durability.

I always verify certifications before recommending ceramic-coated options to B2B clients. The coating technology represents a significant advancement over traditional paint-based finishes that dominated the market for years.

Safety Certifications

| Certification | Standard Bottles | Ceramic-Coated |

|---|---|---|

| FDA Approval | Basic stainless steel only | Full coating system approved |

| LFGB Compliance | Metal components only | Complete product certified |

| REACH Standards | Limited coverage | Comprehensive material safety |

| BPA-Free Status | N/A (metal construction) | Verified coating formulation |

Durability Testing Results

Our factory conducts extensive durability testing that goes beyond industry standards. The ceramic coating undergoes impact testing, thermal cycling, and chemical resistance evaluation. Results consistently show 5-10x longer coating life compared to standard paint finishes2.

The nano-ceramic structure bonds at the molecular level with the stainless steel substrate. This creates a permanent modification rather than a surface application that can peel away. For B2B buyers, this means your investment in branded bottles delivers value for years, not months.

Temperature resistance also exceeds standard coatings. Ceramic-coated bottles maintain their appearance and performance through dishwasher cycles, while painted bottles often show damage after just a few washes3.

Ceramic coatings are FDA-approved, non-toxic, and significantly more durable than standard paint.True

The text confirms FDA-approved, non-toxic materials and superior hardness compared to standard paint.

Ceramic coatings are less durable than standard paint and contain toxic materials.False

The text states they 'significantly exceed standard paint' and use 'non-toxic' materials.

How Does a Ceramic-Lined Bottle Preserve the Pure Taste of a Drink

Taste purity directly impacts user satisfaction and brand perception in ways that B2B buyers often overlook. The drinking experience creates lasting impressions that extend far beyond the initial gift presentation.

Ceramic lining creates a completely inert barrier that prevents any chemical interaction between beverages and the metal container. This eliminates metallic taste transfer, preserves subtle flavors, and maintains the intended taste profile of any beverage.

I noticed this difference personally when testing our ceramic-lined samples against standard bottles. Coffee tasted noticeably cleaner, and even plain water had a fresher quality that standard stainless steel couldn't match.

Taste Comparison Analysis

| Beverage Type | Standard Steel Impact | Ceramic-Lined Result |

|---|---|---|

| Plain Water | Slight metallic notes | Completely neutral |

| Coffee | Muted flavors, metallic aftertaste | Full flavor profile preserved |

| Citrus Drinks | Acidic reaction, off-tastes | No chemical interaction |

| Tea | Tannin interaction with metal | Pure, unaltered taste |

Chemical Inertness Benefits

The ceramic surface creates zero chemical reactivity with any beverage. Standard 304 stainless steel, while genera4lly safe, can still interact at the molecular level with acidic compounds. This is why our material comparison guide recommends 316 steel for acidic beverages - it acknowledges the limitation of standard materials.

Ceramic lining eliminates this concern entirely. The glass-like surface provides the taste purity of glass bottles with the durability and thermal properties of stainless steel.5 This combination delivers premium performance that justifies higher pricing for B2B buyers who understand value.

For corporate gifting, taste quality reflects directly on your brand's attention to detail. When executives start their day with pure-tasting coffee from your branded bottle, they associate your company with quality and thoughtfulness. This psychological impact far exceeds the incremental cost difference.

Ceramic lining prevents metallic taste transfer and preserves drink flavors by forming an inert barrier.True

The text states ceramic lining creates an inert barrier preventing chemical interaction and metallic taste transfer.

Ceramic lining enhances beverage taste by subtly infusing drinks with ceramic minerals.False

The lining is inert, preventing chemical interaction and preserving existing taste, not adding new flavors.

What Should You Consider When Buying a Ceramic-Lined Water Bottle

B2B sourcing decisions require careful evaluation of multiple factors beyond initial price. Ceramic-lined bottles involve additional considerations that impact long-term value and user satisfaction.

Key considerations include coating thickness and application method, temperature ratings for intended use, customization options that work with ceramic surfaces, and minimum order quantities that align with your budget and distribution needs.

My experience with B2B buyers shows that upfront planning prevents costly mistakes. The ceramic coating process requires different customization approaches compared to standard bottles, affecting lead times and design options.

Technical Specifications

| Specification | Standard Range | Premium Options |

|---|---|---|

| Coating Thickness | 10-15 microns | 20-25 microns |

| Temperature Resistance | -20°C to 80°C | -40°C to 120°C |

| Hardness Rating | 3H minimum | 4H+ available |

| Color Options | Limited palette | Custom color matching |

Customization Considerations

Ceramic surfaces require specific printing and engraving techniques. Laser engraving works exceptionally well, creating permanent markings that won't fade or wear away. Screen printing requires ceramic-compatible inks that bond properly with the coating.

Lead times typically extend 2-3 weeks beyond standard bottles due to the additional coating and curing processes6. However, this investment in time delivers significantly longer-lasting results that justify the wait for quality-focused brands.

Minimum order quantities often start higher than standard bottles, typically 500-1000 pieces minimum7. This reflects the specialized manufacturing process and setup costs involved in ceramic coating application.

Cost-Benefit Analysis

The higher initial cost per unit translates to lower cost per impression over the product's lifetime. While standard bottles might cost 30-40% less upfront, their shorter useful life and higher replacement rates often make ceramic-coated options more economical for serious branding campaigns.

I always recommend calculating total cost of ownership rather than focusing solely on unit price. This approach helps B2B buyers justify the investment internally and secure appropriate budgets for quality promotional products.

Coating thickness, temperature ratings, and MOQs are key considerations for ceramic-lined bottles.True

The snippet explicitly lists these as key considerations for sourcing ceramic-lined bottles.

Only initial price and basic design are important when sourcing ceramic-lined bottles.False

The article emphasizes evaluating multiple factors beyond initial price for these products.

Can You Use Ceramic-Lined Bottles for Hot or Acidic Beverages

Temperature and chemical compatibility concerns often limit promotional bottle effectiveness. B2B buyers need assurance that their branded bottles will perform safely across all intended use cases.

Ceramic-lined bottles excel with both hot and acidic beverages due to the coating's chemical inertness and thermal stability. The ceramic barrier prevents any reaction with acidic compounds while maintaining structural integrity at temperatures up to 120°C.

This versatility represents a significant advantage for B2B buyers targeting diverse user groups. Unlike standard bottles that may require usage restrictions, ceramic-lined options handle the full spectrum of beverages without compromise.

Temperature Performance

| Temperature Range | Standard Steel | Ceramic-Lined |

|---|---|---|

| Cold Beverages (0-10°C) | Excellent | Excellent |

| Room Temperature | Good | Excellent |

| Hot Beverages (60-80°C) | Adequate (metallic taste) | Excellent (pure taste) |

| Very Hot (80-100°C) | Limited use | Full performance |

Acidic Beverage Compatibility

The ceramic lining completely eliminates concerns about acidic beverage reactions8. Lemon water, orange juice, coffee, and even sports drinks with citric acid pose no issues for ceramic-coated bottles. This broad compatibility increases user satisfaction and reduces the risk of negative experiences that could reflect poorly on your brand.

Standard stainless steel bottles often develop off-tas9tes with prolonged exposure to acidic beverages. The metal surface gradually oxidizes, creating compounds that alter taste and potentially raise health concerns. Ceramic lining prevents this entirely through its chemically inert surface.

For B2B applications, this means your branded bottles work perfectly for coffee shops, juice bars, fitness centers, and outdoor events where diverse beverage types are common. Users appreciate the versatility, associating your brand with thoughtful design and superior performance.

The thermal properties also enhance the user experience. Ceramic lining helps maintain beverage temperature while preventing heat transfer to the exterior surface. This keeps hot beverages hot longer while ensuring comfortable handling - another detail that reflects positively on your brand's attention to user comfort.

Ceramic-lined bottles are suitable for hot and acidic beverages.True

The ceramic coating offers chemical inertness and thermal stability for both.

Ceramic-lined bottles react with acidic compounds, limiting their use.False

The ceramic barrier prevents any reaction with acidic compounds due to its inertness.

Conclusion

Ceramic-coated stainless steel bottles transform promotional products from short-term marketing materials into long-lasting brand ambassadors through superior durability, taste purity, and justified premium positioning.

-

Scientific review on inert ceramic coatings for beverage packaging. ↩

-

Elaborates on the superior, extended lifespan of these coatings. ↩

-

Online discussion confirms painted vs. ceramic bottle durability differences. ↩

-

Details molecular interaction of 304 stainless steel with acidic compounds. ↩

-

Explains glass properties, supporting the claim of taste purity from glass-like surfaces. ↩

-

Defines "lead time," the key concept extended by production processes. ↩

-

Explains the concept of Minimum Order Quantity (MOQ). ↩

-

Confirms ceramic material safety for food contact, addressing chemical inertness. ↩

-

Confirms off-tastes caused by acidic liquids oxidizing stainless steel bottles. ↩